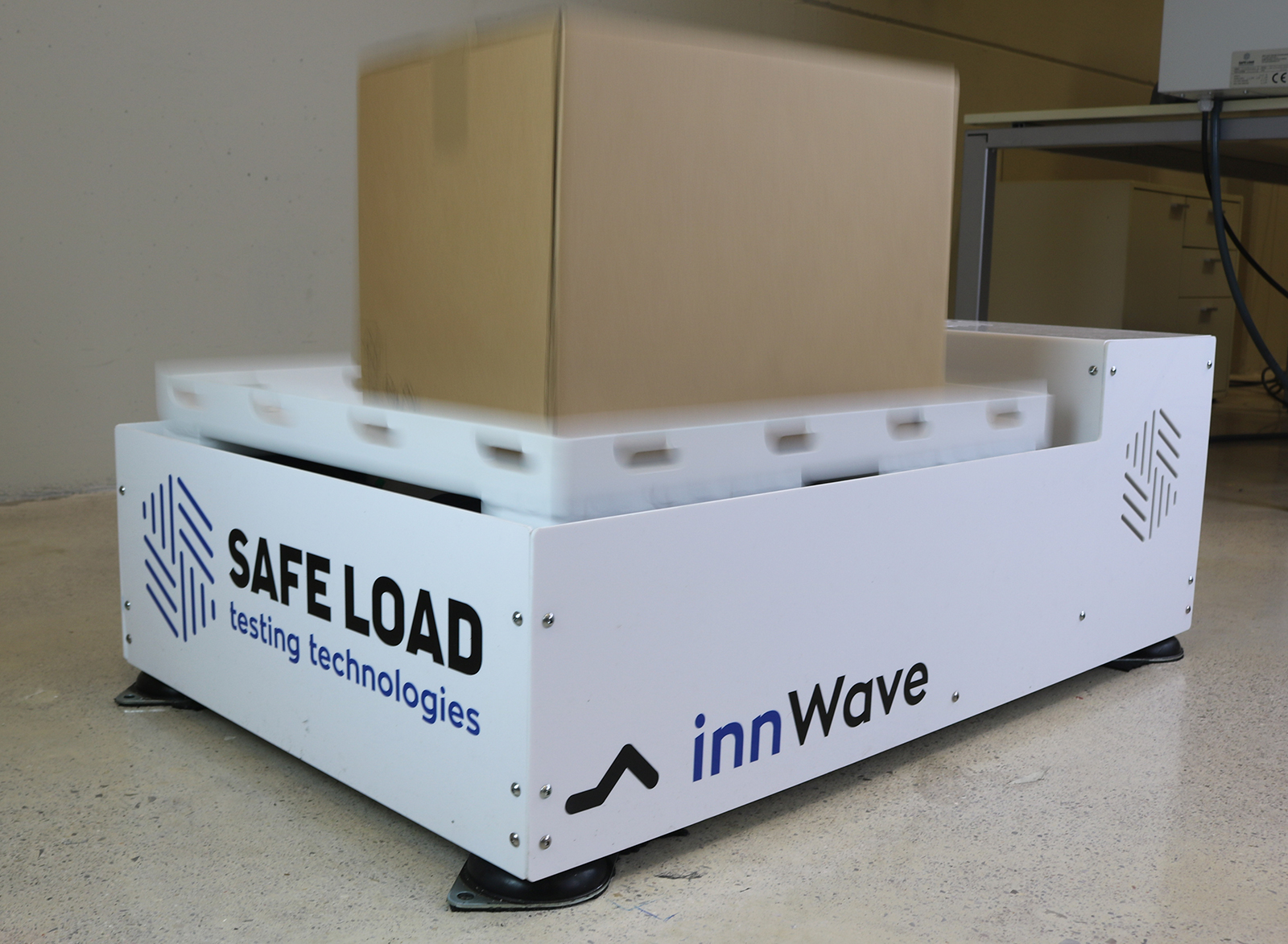

Rotational Vibration Testing System

The Rotational Vibration Test System is the latest innovation developed by the team of experts at Safe Load Testing Technologies.

This is the smallest member of the innWave family and is created to perform rotational vibration tests, regulating the frequency, according to the international standard ASTM D999.

The The Rotational Vibration Testing System is characterized by a stroke of 1 inch (25.4 mm) and a working range between 2.5 Hz and 5 Hz.

The Rotational Vibration Table is designed to perform low vibration shocks in accordance with ASTM D999-08, ISO 2247:2000 and ISTA procedures. Its intuitive control system allows you to choose between several vibration test modes. This vibration system also features a user-friendly control panel and an automatic table leveling system.

Advantages of the Rotational Vibration Test System

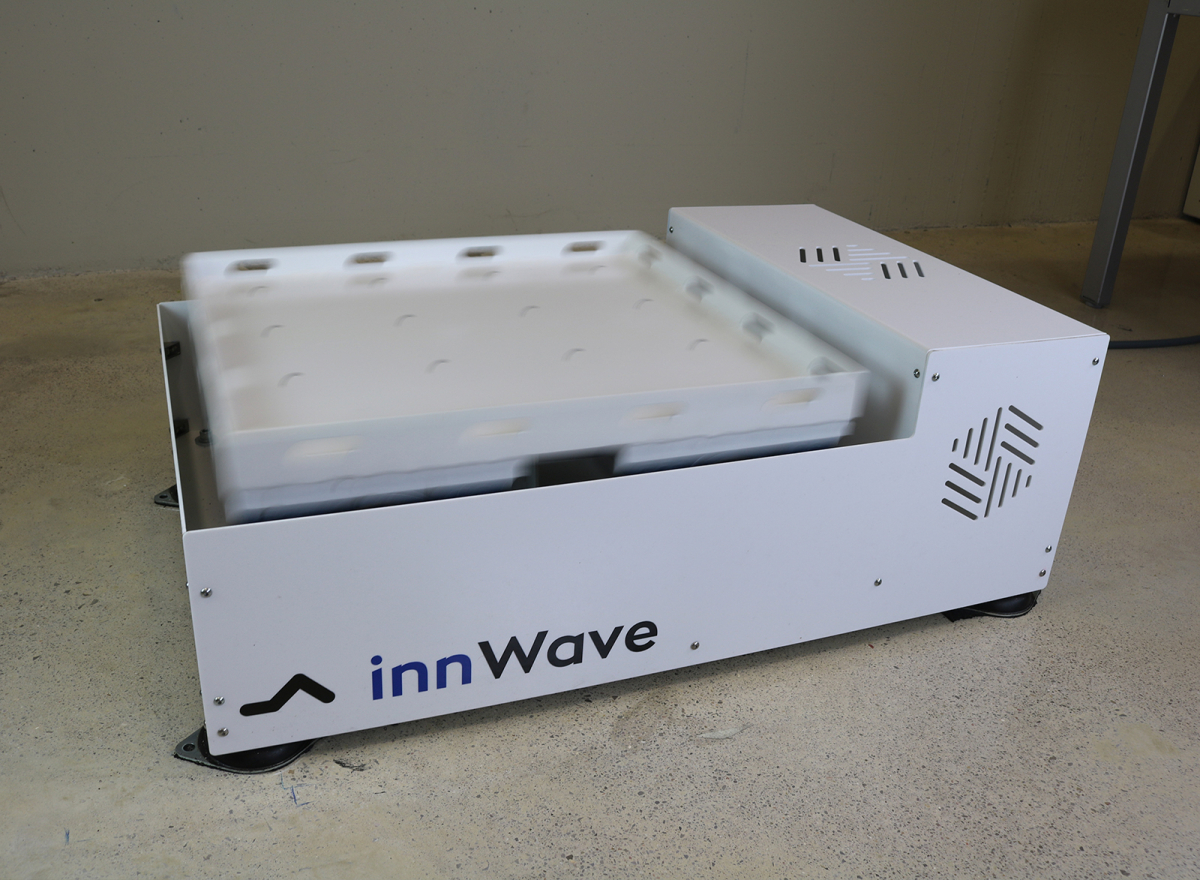

Among the advantages of the rotational vibration test system, note that a special foundation is not required for the operation of the equipment, the design of the shaker provides low transverse components of vibration influences.

The shaker is equipped with an automatic table leveling system and the built-in vibration sensor allows you to obtain objective data on the shock levels on the table and control overloads. The software was developed keeping in mind the needs of testing centers and laboratories.

The system has been developed for testing and product engineers to quickly and accurately characterize vibrations, but our intuitive control software allows our customers without test and analysis experience to use the Rotational Vibration Test System for vibration testing. vibration. This enables our customers to better develop new and better products and systems.

The system requires minimal and inexpensive maintenance.

In addition, the VR System can be placed inside a climatic chamber that allows testing in real climatic conditions.

Product features

- No special foundation required

- Transverse components low vibration shocks.

- Automatic table leveling system

- Control board: The HMI to control the equipment is mounted in the electrical cabinet.

- Intuitive Control System: The control system allows vibration testing of products in the following modes:

- Fixed frequency

- Step-by-step vibration programmable over time at fixed frequencies

- Frequency oscillation

- Arbitrary mode with the function of controlling the correctness of the parameter settings to prevent vibrator failure.

- Meets the fixed frequency test of ASTM D999-08 Standard Test Method for Vibration Testing of Shipping Containers.

- ISO 2247:2000 Low frequency vibration test.

- ISTA procedures.

Revolutionizing Vibration Testing: Advanced Rotational System Delivers Hassle-Free Testing with Real Climate Capabilities

The system has been developed for testing and product engineers to quickly and accurately characterize vibrations, but our intuitive control software allows our customers without test and analysis experience to use the Rotational Vibration Test System for vibration testing. vibration. This enables our customers to better develop new and better products and systems.

Do you want to see our

Rotational Vibration Testing System ?

Industries

Do you want more information about this product?

Complete the following form and we will send you all the necessary information…

Members of