Inverters play a crucial role in both household appliances and industrial machinery. Comprising sophisticated electronic circuitry, inverters need to be tested in various situations, including product performance testing, maintenance checks, and troubleshooting in case of malfunctions or failures. This guide provides a clear introduction to the principal types of inverter testing, the reasons for conducting these tests, essential precautions, and related topics.

Inverters are essential for driving equipment ranging from small electric devices to large industrial machines by varying the speed of their motors. They have two primary functions:

AC power sources have constant voltage and frequency, which differ by region. A converter changes AC from the power grid to DC, and an inverter converts DC back to AC with the required frequency and voltage for specific machinery.

Inverters allow for variable motor speeds, enabling more efficient and user-friendly operation of machinery. Without an inverter, motors run at a constant speed, which can lead to abrupt starts or continuous full-speed operation.

Given their critical role and precise circuitry, inverters must undergo thorough testing to ensure proper functionality and reliability.

Products with an inverter that’s not in optimal condition fail to serve their purpose. When completing a product or machine, manufacturers check whether the inverter is operating as designed.

There are a variety of types of inverter systems, and once a device used to control a piece of equipment like a machine or pump–for example, an inverter panel–fails, it’s too late for testing. Regular testing is necessary to check for inverter issues and signs of impending failures or malfunctions.

When a malfunction occurs, repairs can’t be carried out until the part that malfunctioned is identified. Inverter testing is necessary in order to check for malfunctions of the inverter.

This section introduces insulation resistance testing and voltage/current measurement, two tasks that are sometimes used in inverter testing.

Insulation resistance testing is used to check for degradation in wire insulation. Such testing is performed not only after problems are found, but also on a regular basis to prevent such issues as part of a maintenance regime.

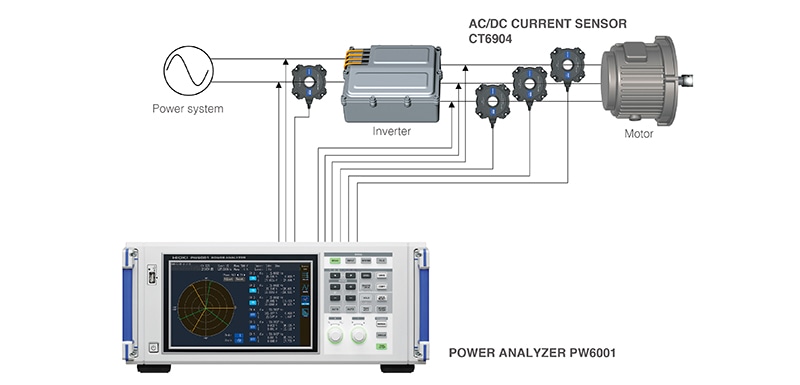

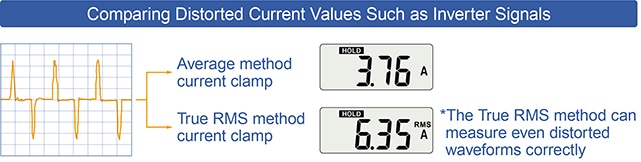

When measuring the voltage and current on the primary side of an inverter, distortions in waveforms can cause differences in measured values. Consequently, it's necessary to use a true RMS voltmeter (digital multimeter) and current meter (clamp meter).

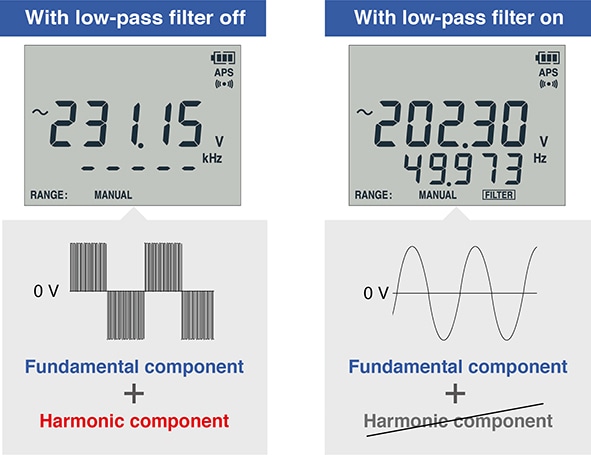

On the secondary side of an inverter, the voltage and current’s fundamental wave includes harmonic components. When measuring the voltage on the secondary side of an inverter, you’ll typically only need the value for the fundamental wave. Please choose a true RMS voltmeter with a filter function that can eliminate harmonic components. You’ll also need a true RMS current meter.

Several precautions should be borne in mind when carrying out inverter insulation resistance testing and voltage/current measurement.

Resistance is measured between the terminals and ground while applying a 500 V test voltage, and the measured value is checked to ensure it is at least 5 MΩ. Insulation resistance measurement consists of applying a high voltage and checking the insulation. Be sure to observe the inspection locations and applied voltages specified by the inverter’s manufacturer when making measurements.

Since the waveform’s frequency varies on the secondary side of the inverter, it’s necessary to take the fundamental wave’s frequency range into account when choosing a voltmeter and current meter.

Inverters enable precise control of motor speeds by converting DC to AC, essential for driving various equipment. Testing inverters is critical for quality assurance, maintenance, and troubleshooting. By following the methods and precautions outlined in this guide, you can effectively test inverters to ensure their optimal performance.