Hydrogen production by electrolysis is growing due to hydrogen’s use as a carbon-free energy source. The International Energy Agency (IEA) projects that the global capacity for hydrogen via electrolysis will grow from around 0.2 GW in 2019 to 160 GW by 2040. Increasing demand and falling costs for solar and wind renewable energy, along with advances in electrolysis technology, are spurring growth in the use of hydrogen to power fuel cells for energy storage, transportation and industrial processes. One example is hydrogen-powered fuel cells for the energy storage and generation of electricity when power plants need additional energy. Other examples of hydrogen usage include hydrogen-powered fuel cells for powering electric vehicles and aviation and as a reactant in industrial processes such as ammonia production.

The electrolysis process, of course, requires electrical energy to create hydrogen. Ideally, energizing the electrolysis process uses reliable (clean) power produced in a cost-effective manner with equipment that does not require excessive floor space.

However, hydrogen production requires significant power, which is a strong consideration when evaluating different programmable DC power supplies. This blog will discuss the basics of hydrogen electrolysis and show how EA can provide a superior solution to the power challenge for reliable, safe, and compact hydrogen electrolysis.

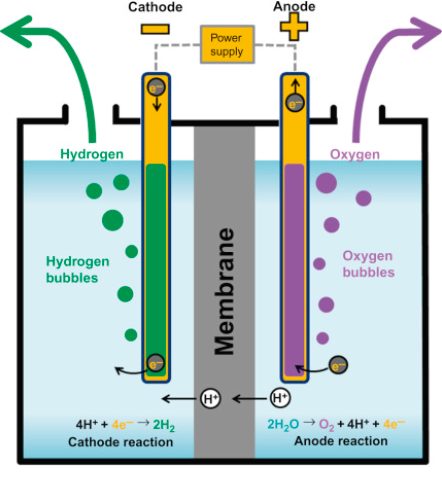

Hydrogen electrolysis is a method of producing hydrogen gas that requires water and electric energy. The process involves passing an electric current through water, H20, which causes the water molecules to break apart into hydrogen ions, H+, and oxygen ions, O-. Hydrogen electrolysis is performed in an electrolyzer containing a membrane permeable to hydrogen ions. The hydrogen ions are attracted to the negatively charged electrode (the cathode) and pass through the membrane to reach the cathode. In contrast, the oxygen ions are attracted to the positively charged electrode (the anode).

At the cathode, the hydrogen ions gain electrons from the power system and become hydrogen gas, H2. At the anode, the oxygen ions lose electrons to the electric current and become oxygen gas, O2. The two gases are collected separately. Figure 1 illustrates the electrolysis process.

The electrolysis process is energy-intensive, as it requires a significant amount of electric energy to split water molecules into hydrogen and oxygen. Producing 1 kg of hydrogen, using solar power as the energy source for a power system requires at least 50 kWh. A facility producing 100 kg of H2/day needs at least a 230 kW power system.

Let’s look at possible solutions for the intense energy requirements for hydrogen production. A modular EA Elektro-Automatik power rack can provide the power necessary for any size hydrogen electrolysis plant. A rack, like the one shown in Figure 2, can provide up to 300 kW of power with up to five EA-PU 10000 6U, 60 kW power supplies. The high density, 6U, 60 kW power supplies allow production floor space savings since only one rack is needed to deliver as much as 300 kW.

An additional 12 racks can combine to generate up to 3.84 MW of total output power. One power supply acts as the controller for up to 63 more power supplies in a master-auxiliary configuration to create a system as large as 64 paralleled power supplies. To ensure a system operates safely, a Share-Bus™ link between all the supplies ensures that each supply shares a portion of the load equally. The Share-Bus link balances the energy delivered to the load evenly among all the power supplies.

As well as protecting a system of paralleled power supplies, the Share-Bus control link can de-energize the output of a defective power supply. Once the defective power supply is removed from the system, the power rack can be re-initialized and continue to output power for the hydrolysis process following a minimum amount of system downtime. Thus, an EA power rack offers extensive scalability to generate up 3.84 MW of fail-safe power.

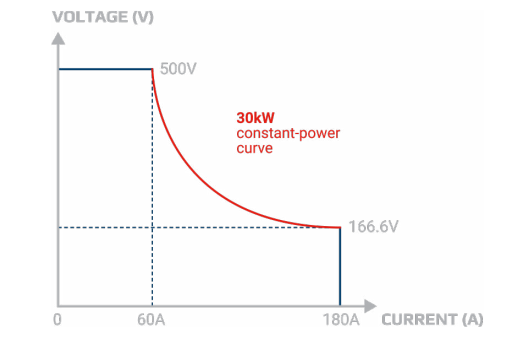

EA programmable DC power supplies have a true autoranging output characteristic (see Figure 3), providing a much wider voltage and current output than a comparable capacity power supply with a conventional rectangular output characteristic. Unlike a rectangular output characteristic power supply that can only deliver full power at one point, the maximum voltage and maximum current point, the EA true autoranging power supplies deliver full power from the maximum rated voltage all the way down to 1/3 of the maximum rated voltage, without the need to stop and switch. The wide voltage and current outputs of an EA autoranging power supply can potentially reduce the size and number of power supplies needed for a system, offering significant cost savings.

Figure 3. Output characteristic of a 30 kW true autoranging EA power supply with a 500 V maximum voltage rating. Note how the power supply can deliver full power from 500 V down to 166.6 V.

Figure 3. Output characteristic of a 30 kW true autoranging EA power supply with a 500 V maximum voltage rating. Note how the power supply can deliver full power from 500 V down to 166.6 V.Now, let’s look at options in monitoring and the choice of interface for automated control of a system. An EA power supply can interface with the USB interface or the Ethernet interface on a PC. Optional interfaces include, among other optional interfaces, a CAN bus interface and a Profibus interface for control from a PLC. Furthermore, EA DC power supplies have a SCPI command operating mode to allow control from PC programs and a Modbus command operating mode for PLC control.

With the Ethernet interface, engineers can provide diagnostic and maintenance support from a remote location to minimize system downtime. Thus a hydrogen electrolysis facility can ensure a cost-effective life cycle for the power rack.

Systems are pre-wired and comply with international safety standards. Power racks, such as shown in Figure 4, are professionally wired and completely documented. Furthermore, EA ships all power racks fully tested to published specifications. All that is required for installation is AC power and system cooling. EA power racks can be air- or water-cooled depending on facility requirements.

Figure 4. The rear of an EA power rack showing highly ordered and secured wiring and the bus bar-assembled parallel output down the center of the rack.

Figure 4. The rear of an EA power rack showing highly ordered and secured wiring and the bus bar-assembled parallel output down the center of the rack.Every aspect of renewable energy seems to be improving year after year, and fuel cell efficiency is no exception. As efficiency continues to grow, the demand will also increase as industries can no longer ignore a viable source of formidable power. Procuring the highest power density supplies will meet your programmable power needs now and higher power production in the future without having to redo your line.