Recent years have seen an aggressive development effort by manufacturers to introduce electric versions of vehicles like automobiles and motorcycles, which mostly have been powered by gasoline engines to date. In addition, there is an ongoing worldwide effort to develop and spur adoption of new technologies for generating electricity from renewable energy sources. Such developmental efforts, which are intended to realize a decarbonized society, are only expected to accelerate in the future.

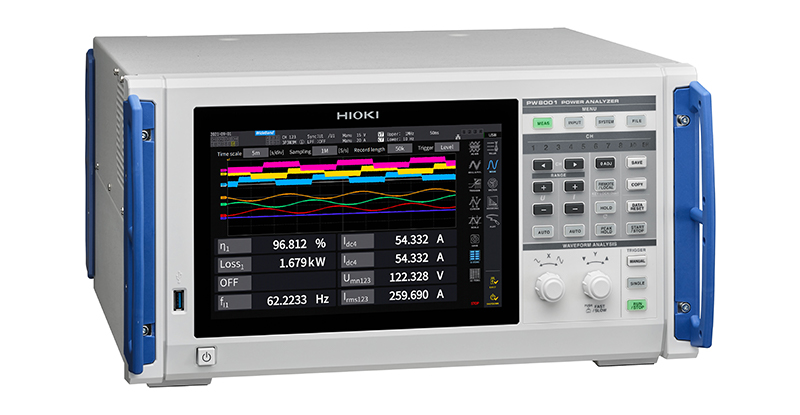

Development of motors and inverters for electric vehicles (EVs) and renewable-energy power generation consists of minuscule, iterative improvements that generally yield power conversion efficiency increases of less than 0.01%. It’s necessary to measure power with an extremely high degree of accuracy since it’s impossible to confirm the benefits of functional improvements if engineers can’t accurately measure minuscule changes in power. Hioki’s Power Analyzer PW8001 delivers the high sampling performance and noise resistance necessary to accurately detect power fluctuations caused by high-speed switching of SiC power semiconductors. Thanks to with measurement accuracy that places it among the most accurate such instruments in the world, the instrument can accurately evaluate power conversion efficiency. In a development environment where dual-motor systems are attracting attention as drive systems for EVs, the PW8001, which can measure up to eight channels of power data, can dramatically reduce measurement man-hours for equipment with a growing number of circuits.

With EVs and renewable energy generation, it’s necessary to maximize energy conversion efficiency by eliminating minuscule energy losses so that energy can be used as effectively as possible. Power measurement is an essential part of evaluating loss and efficiency. It’s here that power analyzers play a crucial role.

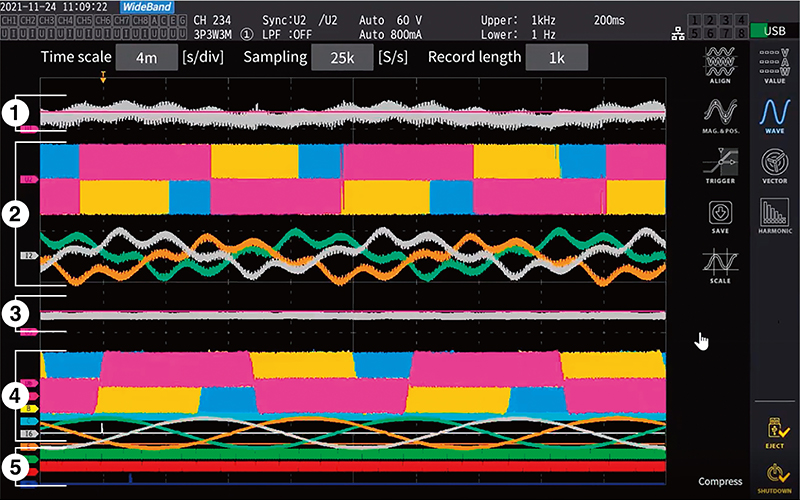

These instruments measure power use by electrical devices like motors and inverters. Unlike standard power meters, power analyzers simultaneously sample a variety of parameters, including current, voltage, torque, and rotational speed, at high speed and accuracy, allowing them to evaluate properties such as power loss, power conversion efficiency, motor characteristics, device response performance, and frequency analysis. In this way, these instruments play an essential role in the development of EVs and technologies for generating electricity from renewable energy sources.

Conventional power analyzers have faced a number of issues.

In developing motors and inverters, where the focus is on realizing improvements in efficiency and loss, engineers work to accumulate small improvements in performance in an effort to quickly realize products that perform better than previous models. For example, the performance of 100 kW-class drive motors used in EVs increases in increments of several watts. This iterative process rests on the accumulation of extremely small improvements. Absent the ability to measure such tiny performance improvements accurately and with a high degree of reproducibility, engineers are unable to determine whether a given change in measured values is evidence of an improvement or simply a matter of chance. With each successive year, instruments are subject to increasingly demanding requirements for functional improvements as well as measurement accuracy and measurement reproducibility.

Power semiconductors capable of accommodating high voltages and high-speed switching are used to control equipment that handles large amounts of power, for example EVs and systems used to generate electricity from renewable energy sources. The transition to next-generation power semiconductors like SiC and GaN devices has continued apace in recent years, and manufacturers continue to boost voltages and switching speeds.

As voltages rise, so does the need for instruments that can safely measure them. As switching speeds increase, measurement frequencies rise, creating demand for measurement across a broader band of frequencies. Higher frequencies also create demand for greater resistance to noise.

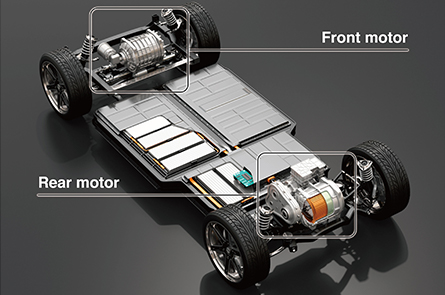

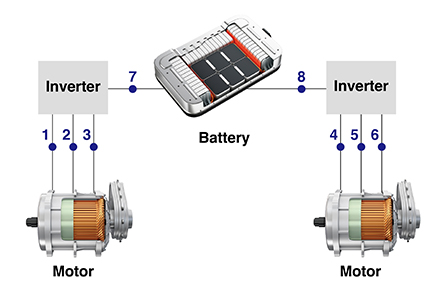

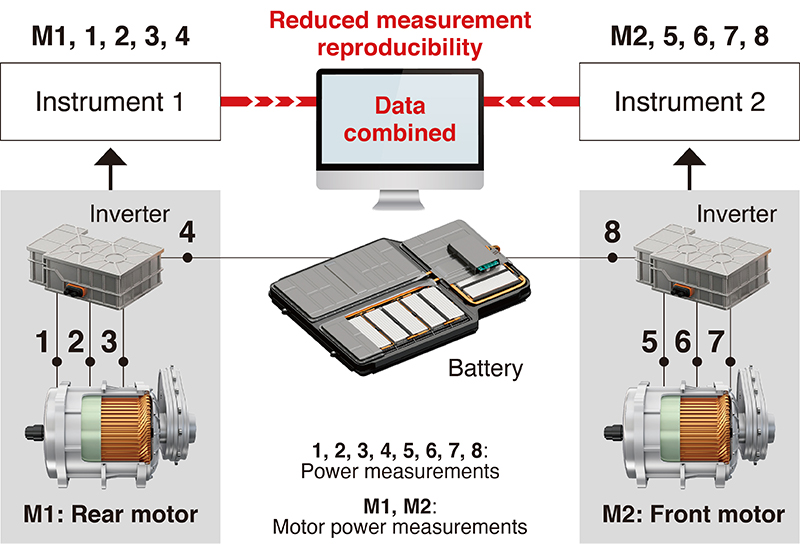

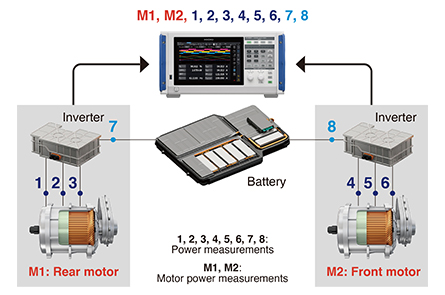

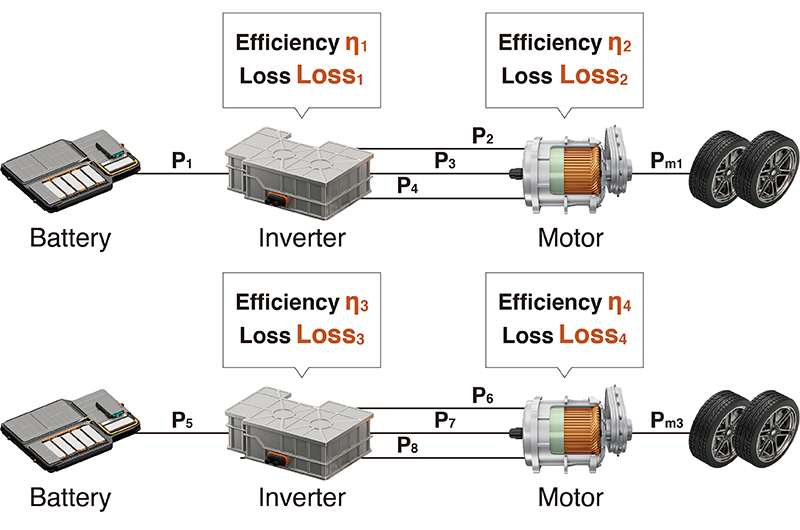

Dual-motor systems in EVs and power interchange systems in smart houses are incorporating increasing numbers of circuits in an effort to make effective use of energy. For example, linkages between the front and rear motors are important when evaluating the performance of dual-motor systems, which are used as drive systems in EVs. Instruments must simultaneously measure the front and rear motor power as well as the input and output power for the each motor’s inverter.

Measurement requires a separate channel for each measurement location. However, if a single instrument does not provide enough channels, multiple instruments must be used, creating difficulties with synchronizing the measurement data update timing. This issue reduces stability when measuring efficiency and loss and increases measurement times and the number of man-hours needed to integrate data.

The PW8001 resolves every problem faced by conventional instruments.

In order to accurately evaluate minuscule power changes, it’s important to accurately measure power in every band, from DC to high frequencies. The instrument’s measurement accuracy is key to this ability. The PW8001 delivers power measurement accuracy that’s among the highest of any such instrument in the world, with a fundamental accuracy of ±0.03%, DC accuracy of ±0.05%, and 50 kHz accuracy of 0.2%. The product offers exceptional measurement accuracy across a wide frequency band, including 50 Hz/60 Hz, DC, and 50 kHz, allowing accurate evaluation of power conversion efficiency.

In order to measure high-speed switching of next-generation power semiconductors, an instrument needs to provide high sampling performance and high noise resistance. The PW8001 delivers exceptional sampling performance with a sampling frequency of 15 MHz and 18-bit sampling resolution. Since the instrument also provides high noise resistance of 110 dB/100 kHz, it can measure power for measurement targets with substantial noise at high frequencies with excellent reproducibility.

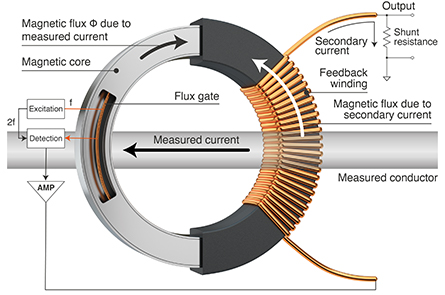

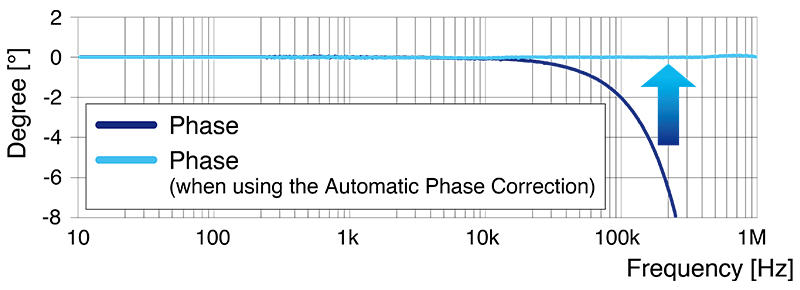

Current sensor performance is also important when measuring power in high-power equipment. Current sensor performance has a significant impact on power measurement accuracy and work efficiency. High performance is also necessary in order to ensure the reproducibility of measurement results.

In addition to power analyzers, Hioki develops and manufacturers its own current sensors. By combining Hioki power analyzers and current sensors, customers can gain optimal performance from their measurement setup.

In addition, power analyzers provide functionality for automatically correcting phase error, a process that in the past required users to enter a correction value for each current sensor. Minuscule individual differences between different sensors of the same model are also corrected automatically. This approach eliminates the possibility of an operator forgetting to perform the correction process while reducing measurement setup man-hours and boosting measurement accuracy and reproducibility.

The PW8001 supports 1500 V DC CAT II and 1000 V DC CAT III measurement, allowing high voltages to be directly inputted and measured safely. This capability ensures the instrument will be able to measure equipment used in EVs and renewable energy generation, both areas where voltages will continue to rise going forward.

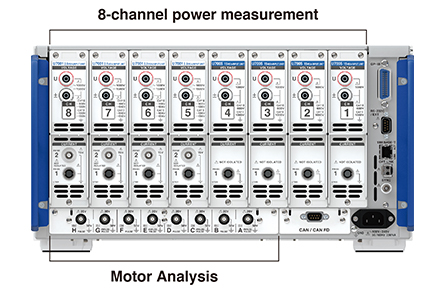

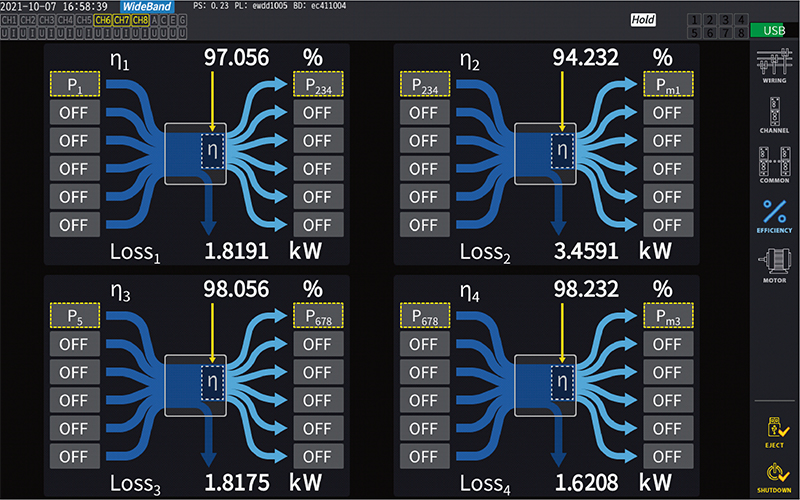

A single PW8001 can measure power across eight channels. For example, in an EV’s dual-motor system, the instrument can simultaneously measure the power for both motors (two torque circuits and two encoder output circuits). In this way, it can measure the performance of dual-motor systems in an efficient and highly reproducible manner. A single PW8001 can measure next-generation motors and inverters, which use an increasing number of circuits.

Hioki used a Power Analyzer PW8001-11 (with motor analysis function) and current sensors to measure power for front and rear motors as well as power input and output for their two inverters and then calculate the power efficiency and loss for each.

Drive systems with four in-wheel motors are expected to emerge as a future EV technology. The PW8001’s four-motor analysis mode can accept signals from torque meters and tachometers as input and use the resulting data to simultaneously analyze four motors. This capability allows the instrument to be used in the evaluation of systems that control individual wheels. In addition to capabilities including high accuracy and its ability to accommodate high voltages and high frequencies, Hioki is working to add functionality and make improvements to resolve customers’ issues.

For example, two PW8001 instruments can be connected with a fiber-optic cable*1, allowing one instrument to aggregate both instruments’ measured values in order to accommodate measurement targets with a growing number of circuits. The resulting setup can simultaneously analyze up to 16 channels of power data while displaying and recording efficiency and loss data on one instrument.

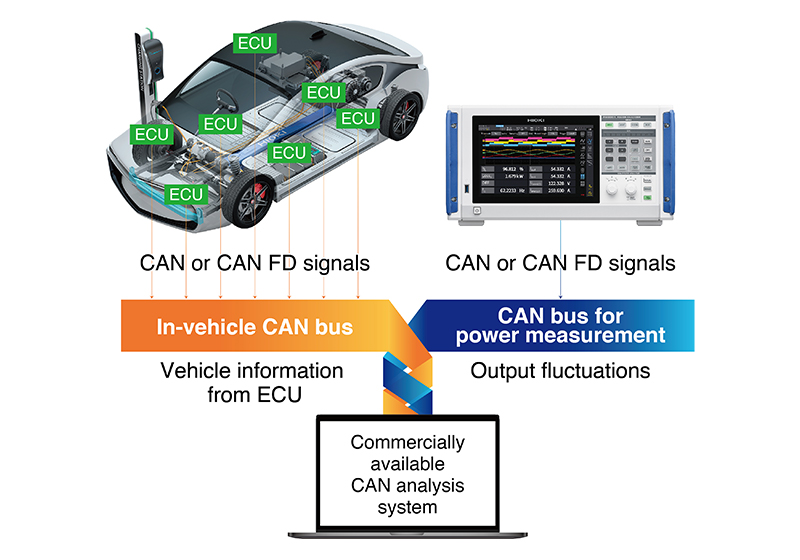

The PW8001 functionality improvements are in progress for use in the automotive industry that allows measurement data to be output as CAN/CAN FD signals*1. As a result, the instrument can aggregate an array of vehicle-related data, including not only voltage, current, efficiency, and loss, but also data from ECUs for batteries and motors, without any time discrepancies, making possible comprehensive evaluation.

The means of transporting people and goods are transitioning to electric drivetrains, from automobiles and motorcycles to construction machinery, ships, and aircraft. As we look towards a decarbonized society, adoption of electrical generation using renewable energy sources is rising year by year, along with generating efficiency. Going forward, Hioki will continue to pursue a diverse program of product development in order to help ensure that a variety of power-using devices can utilize energy as efficiently as possible.