Revolutionizing Railway Technology with Advanced Battery Test Solutions

Battery solutions designed for a new eraVersatile Test Solutions for Battery Powered Electric Trains

Battery-powered electric trains are revolutionizing mass transportation, offering benefits like noise reduction and the freedom from overhead lines. To ensure these trains meet performance and safety standards, robust testing is essential. EA Elektro-Automatik provides cutting-edge battery test equipment tailored for this new era. The PSB Series of bi-directional power supplies simulate DC-DC converters, eliminating the need for real batteries during test. The PSI Series offers flexible waveform generation for EN 50155-2017 compliance testing. Additionally, our ELR Regenerative DC loads deliver optimal power density for extended battery life testing in Li-ion and fuel cell technologies.

The EA Elektro-Automatik PSB Series takes battery testing to the next level, offering seamless transitions between charging and discharging cycles. This series not only regenerates energy back into the local grid but also comes standard with pre-installed battery test software for both lithium-ion and lead-acid batteries. If you’re looking to elevate your battery testing and simulation capabilities, look no further than these cutting-edge products.

Related Products

PS / PSI Autoranging DC Power Supplies

Turnkey Power Racks

Why Partner with W5 Engineering?

Expertise

At W5 Engineering, we specialize in power electronics, providing unmatched knowledge of EA Powered products. Our team of technical sales engineers ensures you find the perfect solution for even the most complex requirements.

Custom Solutions

We deliver customized configurations and integrations tailored to your unique applications. Whether for R&D, production, or testing, W5 Engineering ensures your power systems meet exact specifications.

Rapid Shipping

With on-hand inventory and advanced logistics, we minimize lead times to keep your projects on track. Enjoy seamless delivery and peace of mind with our reliable shipping network.

Customer Support

Application Solutions

Battery Testing

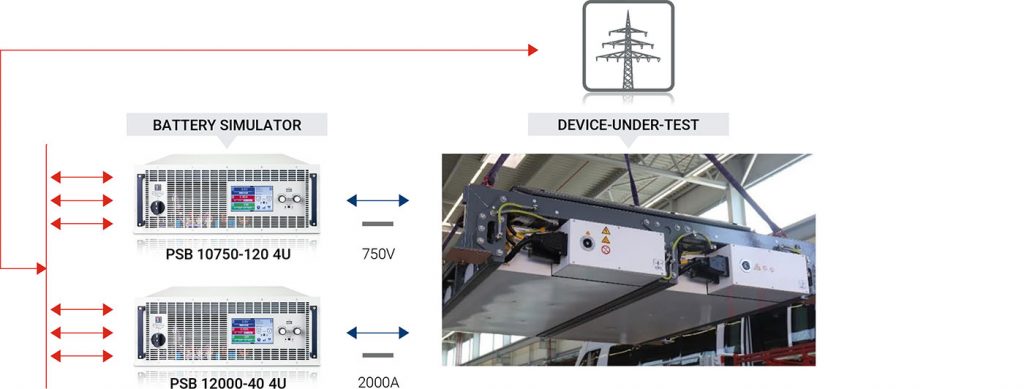

For long-distance electric trains, fuel cells combined with Li-ion rechargeable batteries represent the future of stable, high-capacity power sources. The main challenge for design engineers in the locomotive industry is efficiently managing energy flow between the fuel cells, Li-ion batteries, and DC-DC converters. EA Elektro-Automatik’s programmable power supplies serve as versatile battery simulators, enabling engineers to conduct a variety of tests and expedite time-to-market.

EA Advantages

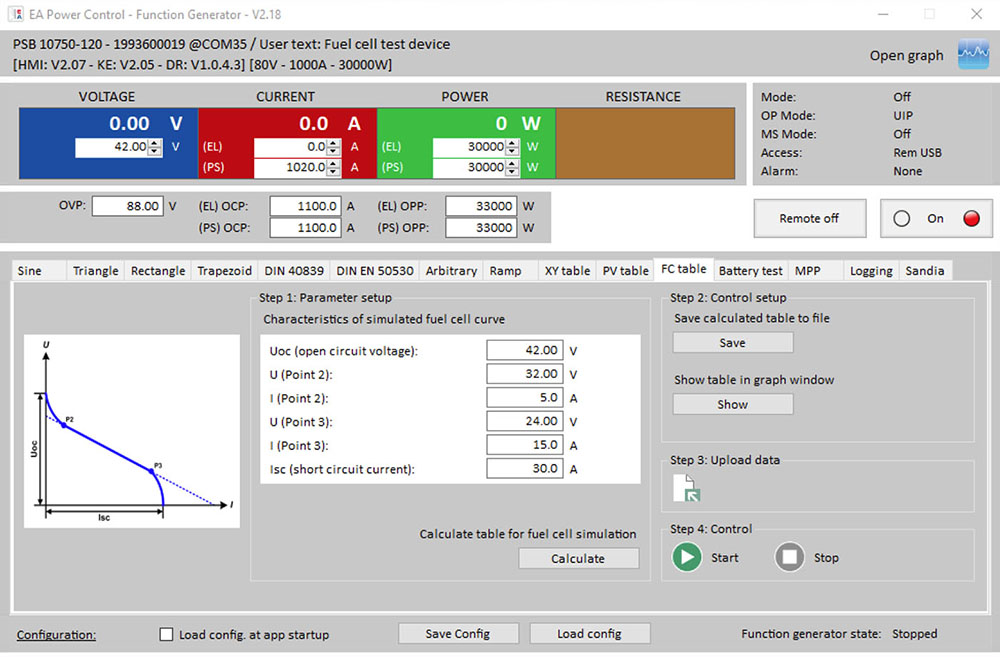

Fuel Cell Simulation in EA Power Control

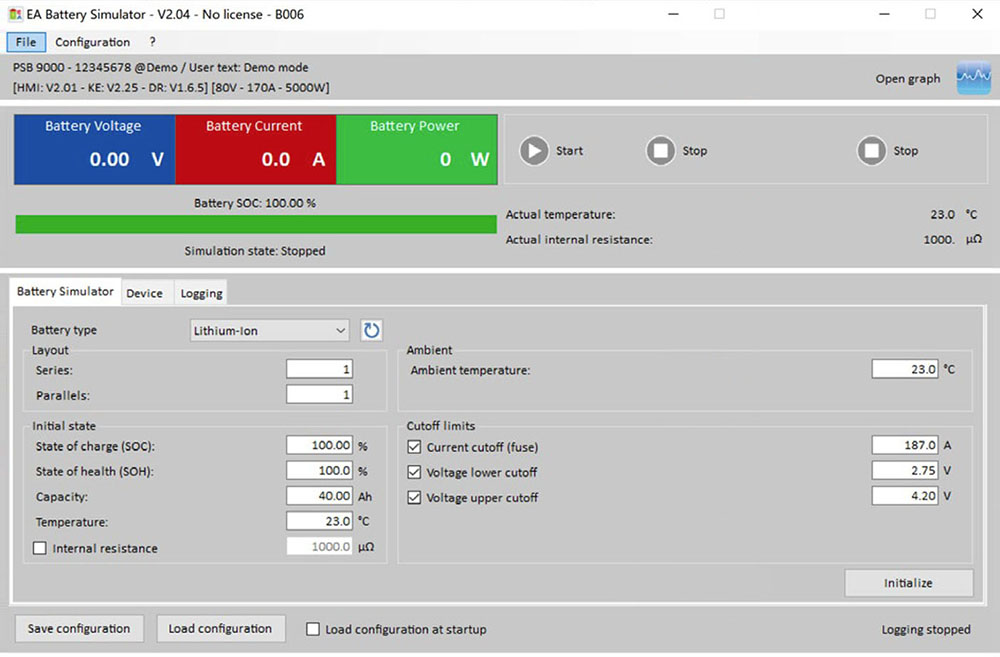

Battery Simulation in EA Battery Simulator

DC-DC Converter and Dynamic Charging

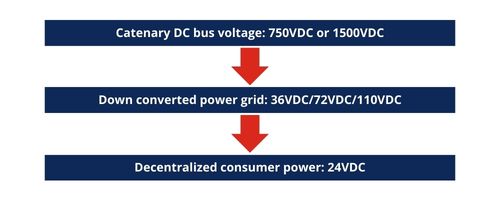

Just like your smartphone, electric trains require efficient charging systems. A basic layout of an electric train’s power distribution includes components like the battery charger, DC-DC converter, DC-AC inverter, and onboard amenities like lighting and air conditioning. To ensure these systems function reliably under varying environmental conditions, a diverse set of programmable DC power supplies is essential. Below is a simplified diagram of and electric train’s power distribution system.