EA-BCTS 10300 Series

Optimized for User Safety and Future Ready EV Battery Technology

High-Efficiency Battery Testing Systems: Compact, Automated, and Scalable

Introducing EA’s turn-key battery testing solution, designed for user-friendly operation and built-in safety features for both the operator and the battery. Their intuitive, customizable touchscreen interface and specialized Battery Test Software (EA-BCTS) make it a complete, integrated test solution.

Space-Efficient & Adaptable to Emerging Technologies

EA’s battery test system requires just one-third of the floor space compared to the competition, a single 300 kW rack consumes only 6.5 sq ft. It’s a future-proofed solution, fully adaptable to new EV battery technologies.

Modular Flexibility & High Power Density for the Future of Test.

EA’s system is modular and customizable, allowing for easy unit swaps without the need for a service technician. It offers the highest power density in a single system, with up to 2,400A per rack and a total capacity of 30,720A. Achieve 300 kW in a single 42U high rack, expandable through parallel racks up to 3.84 MW.

Power Control and Measurement Module (PCMM)

Equipped with a 24in touch panel display, EA’s system offers a user-friendly interface for advanced power control and measurement, ensuring you stay ahead in the fast-evolving battery technology landscape.

Why Choose EA's Battery Testing Solution Over the Competition?

Streamlined Efficiency and Uninterrupted Testing

Unlike our competitors, who require separate racks for programmable power supplies, programmable loads, and another for an industrial PC, test equipment, and communications systems, our integrated solution offers a more streamlined and efficient setup.

Continuous Testing with Adaptive Power Ranges

Battery packs in our system operate at controlled temperatures and are set in a specific battery pack configuration and power rating. Unlike traditional systems that may require test interruptions to change instrument range as the battery pack voltage fluctuates, our advanced technology allows for seamless transitions, ensuring uninterrupted and accurate testing.

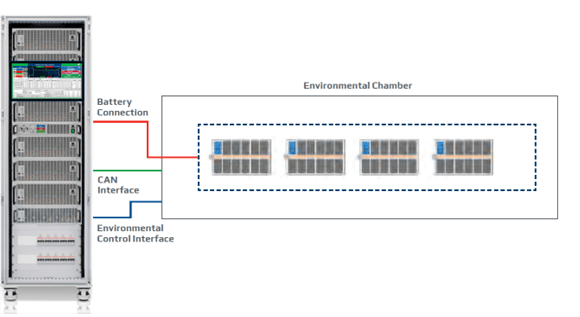

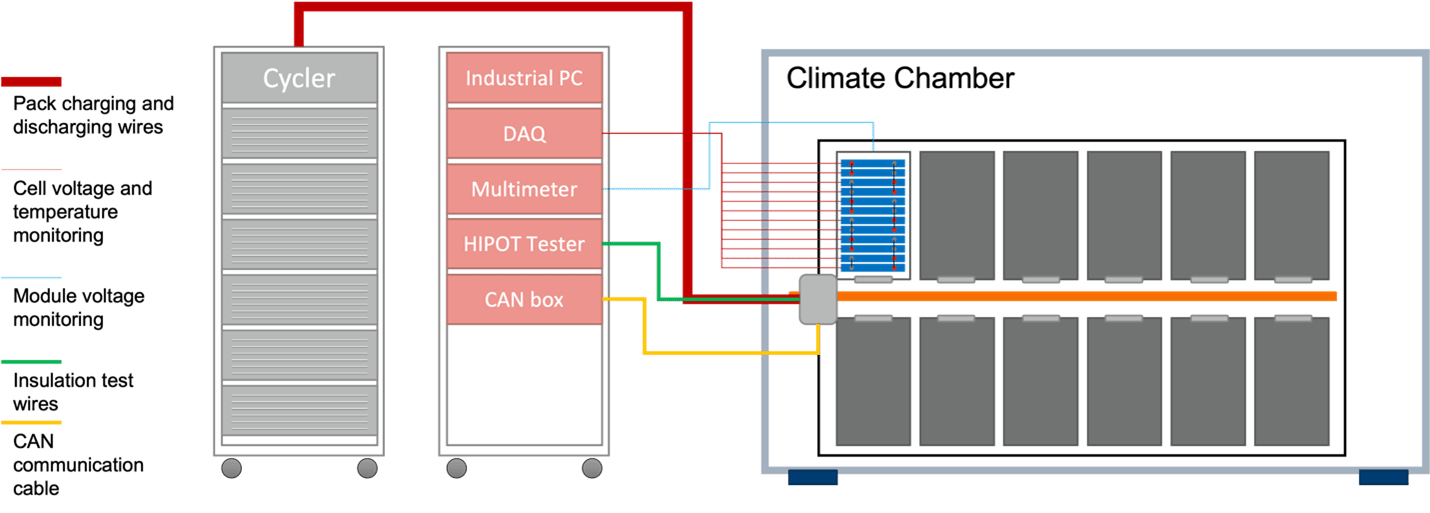

A typical, non EA multi-rack battery pack testing system

Compared with the EA-BTS 10300 System that integrates all the testing and communications into a single rack

The EA-BTS 10300 system sets itself apart from conventional test systems with its TRUE autoranging feature. This unique capability allows the programmable power source to deliver the necessary power across a broad spectrum of voltage conditions, offering unparalleled flexibility and efficiency in battery testing.