Reliable, Fail-Safe DC Programmable Power Supplies

EA Power racks for electrolysis plantsPaving the Way for Green Hydrogen Energy

Harnessing surplus electricity from renewable sources like wind and solar, electrolysis plants convert this energy into hydrogen, which is then stored in pressurized tanks. This stored green hydrogen serves as a versatile energy reservoir, capable of powering fuel cells during periods without wind or solar availability. Additionally, these fuel cells can act as electric drives for a range of vehicles, including passenger cars, buses, and trucks, further expanding the applications of green hydrogen.

Related Products

Optimizing Hydrogen Production with EA’s High-Density Power Solutions

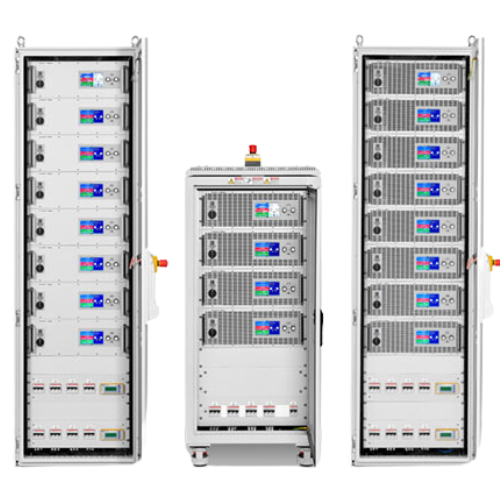

As the global demand for green hydrogen escalates, electrolysis plants worldwide are under pressure to maintain consistent and reliable hydrogen production. To meet this growing need, these facilities are increasingly adopting cutting-edge, fail-safe DC programmable power supply technologies like EA-PU 10000 6U and EA-PUB 10000 6U. EA Elektro-Automatik’s Modular Power Rack systems offer a fully turnkey, modular rack solution, delivering a host of essential advantages to hydrogen energy electrolysis operations. These high-density power solutions not only ensure reliability but also drive the efficiency and scalability required for the burgeoning hydrogen economy.

Why Partner with W5 Engineering?

Expertise

At W5 Engineering, we specialize in power electronics, providing unmatched knowledge of EA Powered products. Our team of technical sales engineers ensures you find the perfect solution for even the most complex requirements.

Custom Solutions

We deliver customized configurations and integrations tailored to your unique applications. Whether for R&D, production, or testing, W5 Engineering ensures your power systems meet exact specifications.

Rapid Shipping

With on-hand inventory and advanced logistics, we minimize lead times to keep your projects on track. Enjoy seamless delivery and peace of mind with our reliable shipping network.

Customer Support

Optimized Power Solutions for Hydrogen Electrolysis

Maximize Uptime and Efficiency with EA's Programmable DC Power Supplies

EA’s Modular Power Racks offer unparalleled reliability, designed to minimize downtime in hydrogen electrolysis production. Our innovative modular design ensures quick component changeouts and seamless system operation, eliminating the limitations of traditional, rigid energy systems. Plus, automatic reconfiguration capabilities guarantee uninterrupted power supply for hydrogen generation.

High-Density DC Power Supplies: EA-PU 10000 6U & EA-PUB 10000 6U

Engineered for high-power hydrogen production, our EA-PU 10000 6U and EA-PUB 10000 6U programmable DC power supplies integrate seamlessly into EA’s Modular Power Racks. Achieve the highest power density within a compact 42U rack footprint, customizable to meet specific application needs.

Streamlined Operation with True Autoranging and Intuitive Interfaces

Experience cost and space efficiency with EA’s true autoranging feature, enabling comprehensive testing and programming through a single device. Our user-friendly touchscreen and remote interfaces offer quick, intuitive control, ensuring safe and efficient distant operation.

EA Advantages

Based on EA’s PU and PUB supply instruments, the turnkey modular rack solution allows fast changes or simplified system expansion to drastically reduce downtime

When four racks are paralleled together

For more testing capability with just one device

Including CAN, CANopen, EtherCAT, RS232, Profibus, Profinet, Modbus, Ethernet

To adapt to any environment

Programmed, prewired, and ready to put into production

High operational value. Dependable power.

Scalable

Customize EA-Power Racks to adapt to voltage and current requirements and parallel units for power up to 3.84 MW

Automation

Seamlessly integrate into electrolysis plant production with remote functionality for safe operation.

Service-friendly

Integrated Ethernet interfaces allow for remote maintenance and diagnostics. Modular design automatically reconfigures as needed for reliable, steady power.

Compact

Highest-power density with the smallest footprint in the industry. Additional features, including true autoranging, negates the need for additional equipment.

Plug and Play

EA turnkey racks require no programming, wiring or set-up before use and arrive fully tested.