Navigate the Future of Battery Technology with Advanced Testing Solutions

Source and Sink Power at 96% EfficiencyAdvanced Battery Testing Solutions for Modern Battery Technologies

The EA Elektro-Automatik PSB Series takes battery testing to the next level, offering seamless transitions between charging and discharging cycles. This series not only regenerates energy back into the local grid but also comes standard with pre-installed battery test software for both lithium-ion and lead-acid batteries. If you’re looking to elevate your battery testing and simulation capabilities, look no further than these cutting-edge products.

Seamless Charging and Discharging

Customizable Cycles

Versatile Testing Functions

Why Partner with W5 Engineering?

Expertise

At W5 Engineering, we specialize in power electronics, providing unmatched knowledge of EA Powered products. Our team of technical sales engineers ensures you find the perfect solution for even the most complex requirements.

Custom Solutions

We deliver customized configurations and integrations tailored to your unique applications. Whether for R&D, production, or testing, W5 Engineering ensures your power systems meet exact specifications.

Rapid Shipping

With on-hand inventory and advanced logistics, we minimize lead times to keep your projects on track. Enjoy seamless delivery and peace of mind with our reliable shipping network.

Customer Support

Application Solutions

Battery Testing

Battery Recycling

Battery Simulation

EA Powered Advantages

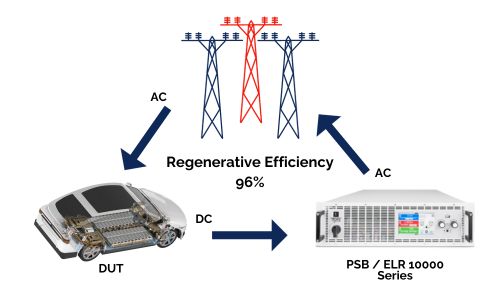

Regenerative Technology ROI Advantages

Typical cost for 1 kilowatt hour = $0.10

Hourly cost:

Example: 100 kWh consumption = $10

Monthly cost:

24 hrs/day, 20 days/month = $4,800

Yearly cost for resistive loads = $57,600

Yearly cost for 96% efficient ELRs = $2,304

Yearly Savings with EA ELRs = $55,296

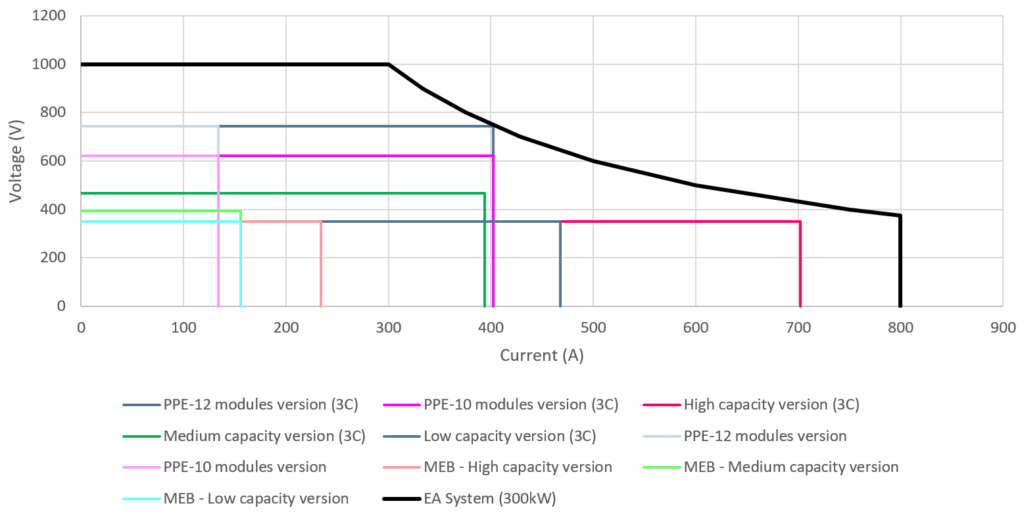

EA's Autoranging Solution Compared

Battery Testing

As battery technology evolves, becoming smaller and more efficient, the need for advanced, flexible, and responsive battery test equipment is paramount. The PSB bidirectional programmable DC power supply series by EA Elektro-Automatik offers a comprehensive solution for cutting-edge battery testing.

The PSB bidirectional programmable DC power supply can effortlessly transition between charging and discharging batteries and comes equipped with various test functions compatible with the PSB, PSI, EL, and ELR series. Whether you need standard or custom charge and discharge cycles, EA provides the ideal equipment and expert guidance for effective and safe battery testing.

Battery Charging

During the development and testing phases, electric vehicles (EVs) like e-bikes, hybrid cars, and full-electric trucks require medium- to high-power battery chargers. These chargers often integrate into a comprehensive battery test system designed to conduct cycle, performance, and age tests. Such test setups typically feature customized control, monitoring, and safety mechanisms suited to the specific battery type being tested.

Battery Simulation

Use EA's bidirectional DC power supplies to simulate lead-acid and lithium-ion batteries

Bidirectional DC power supplies are ideal for battery simulation due to their dual capabilities of sourcing and sinking power. Elektro-Automatik’s Battery Simulator software enhances this by enabling accurate simulation of both lead-acid and lithium-ion batteries, replicating their electrical and chemical characteristics during charge or discharge cycles. This technology allows test engineers to precisely emulate battery power for devices that either charge or draw energy from batteries.

In collaboration with Germany’s esteemed Fraunhofer Institute, EA Elektro-Automatik crafted algorithms based on years of research to simulate batteries with a high level of accuracy. These algorithms enable quick simulation of battery cells at specific states of charge (SOC), eliminating the need to wait for actual charging or discharging. The simulations can be customized using various parameters such as battery capacity, internal resistance, ambient temperature, and even state of health (SOH).

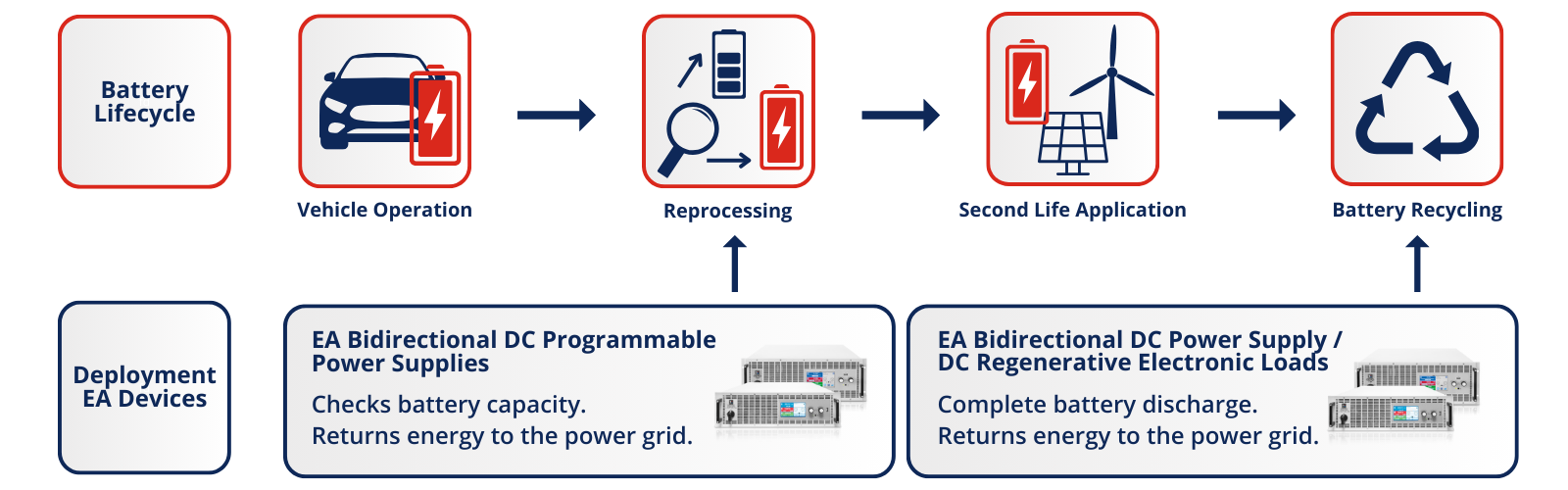

Battery Recycling

Addressing the major challenge of sustainability in electromobility

To pave the way for sustainable electromobility, the efficient recycling and second-life applications of lithium-ion and lithium-ion polymer batteries will soon become critical. New industries and companies are emerging to tackle this challenge. EA Elektro-Automatik’s EA-BT 20000 TRIPLE series enhances your battery recycling process by offering regenerative loads and bidirectional programmable DC power supplies that make the process efficient, flexible, economical, safe, and sustainable.

Second-life Use

Maximize Battery Second-Life Use with Bidirectional DC Lab Power Supplies

The ultimate aim is to repurpose electromobility batteries for second-life applications, such as energy storage for renewable sources like solar and wind power. To assess the remaining capacity, batteries are first fully charged and then systematically discharged. During this process, both the state of charge (SOC) and the state of health (SOH) are measured, and the energy is efficiently regenerated back into the power grid at an efficiency rate exceeding 96%. EA Elektro-Automatik’s bidirectional programmable DC power supplies are perfectly engineered for this task.

Final Recycling

Unlock Full Battery Discharge with Regenerative Electronic Loads

Once rechargeable batteries reach the end of their second-life cycle, they undergo a final recycling process aimed at reclaiming as many components as possible for new lithium-ion batteries. Before disassembly, these batteries must be fully discharged to mitigate risks like hazardous voltage or fire, while also utilizing any residual energy. EA Elektro-Automatik’s regenerative electronic loads offer an efficient solution for this critical step in battery recycling.