Fuel Cell Testing and Simulation

The future of clean energy relies on precision

State-of-the-art solutions for fuel cell testing and simulation, designed to meet the demands of this rapidly evolving industry

EA Elektro-Automatik’s regenerative loads are not only accurate and fast but also cost-effective, equipped with a comprehensive set of features for testing fuel cell resistance, performance, and lifespan.

EA’s bidirectional power supplies enhance operational flexibility and reduce costs by simulating various fuel cell characteristics at the touch of a button. Designed for versatility, EA’s devices are suitable for testing and simulating fuel cells in a wide range of applications. With the fuel cell market currently expanding at a 30% growth rate due to factors like government initiatives and economic incentives, the need for flexible, cost-effective testing solutions has never been more critical.

Application Solutions

Fuel Cell Stack Performance Test

EA Elektro-Automatik’s ELR 10000 4U series of electronic loads provides a comprehensive range of dynamic loading tests, enabling precise fuel cell characterization.

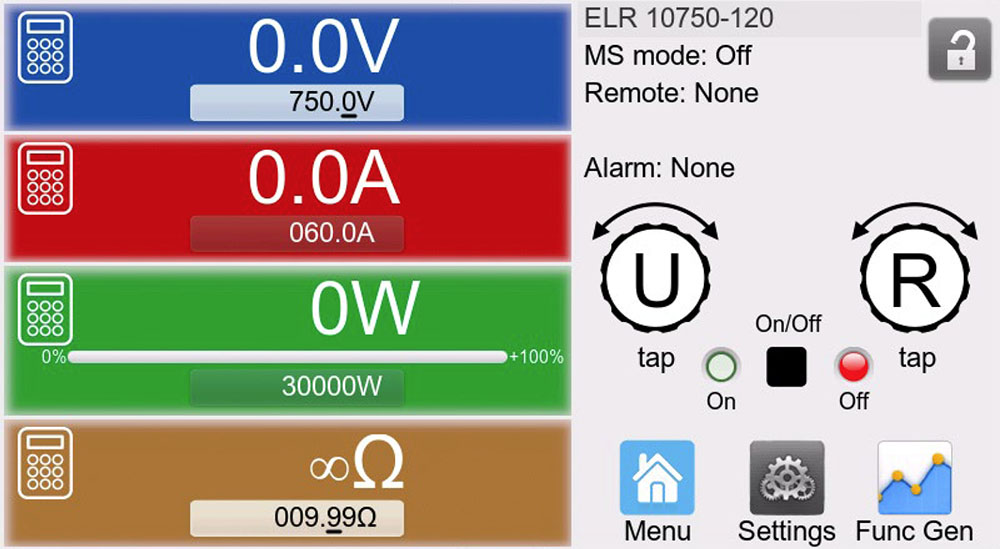

Constant Resistance Mode

It can be easily adjusted via the intuitive HMI (Human Machine Interface) for altering the resistance value.

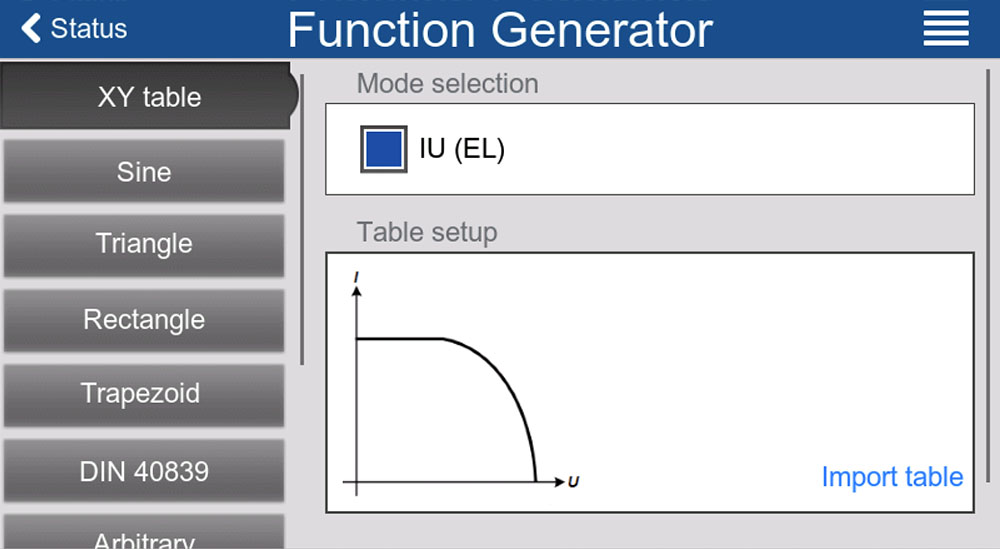

XY Table

This option is particularly useful for non-linear output characteristic verification.

Fuel Cell Stack Durability Test

Automotive standards demand 5,000 hours of testing, while stationary storage needs exceed 10,000 hours. Despite the use of accelerated test profiles like step and triangular potential cycles, significant energy loss can occur.

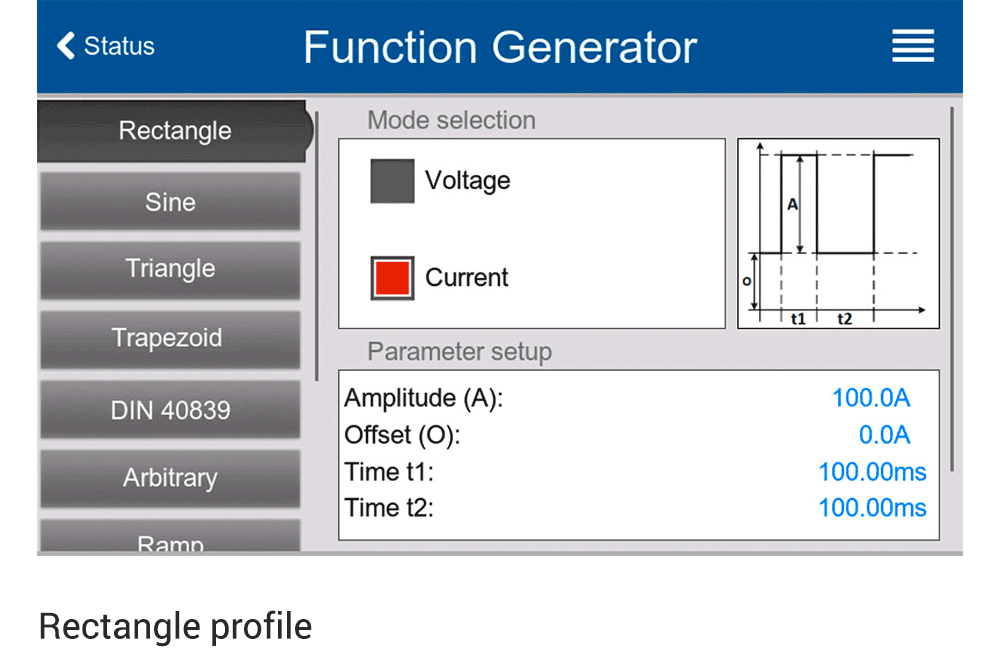

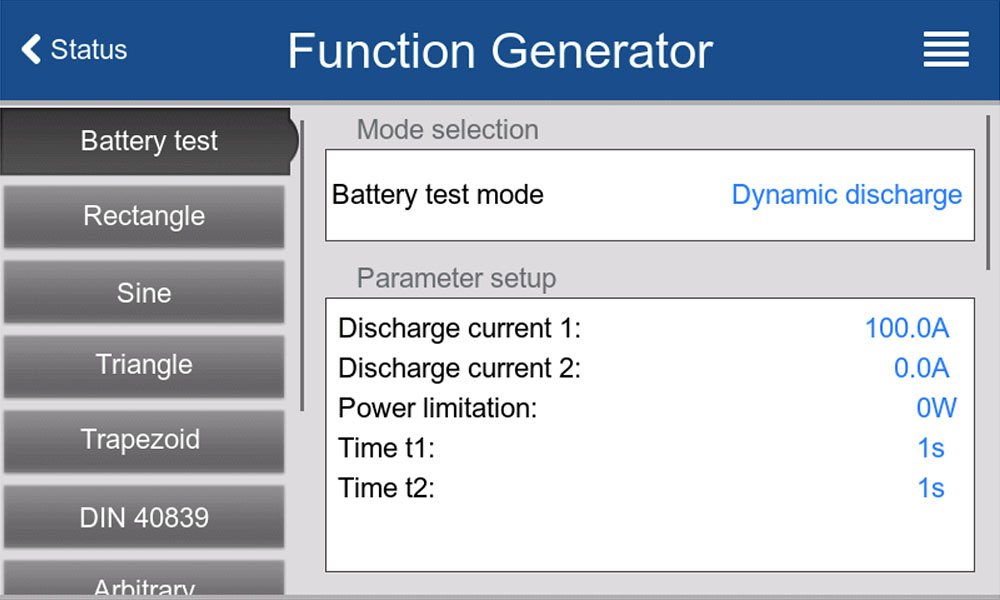

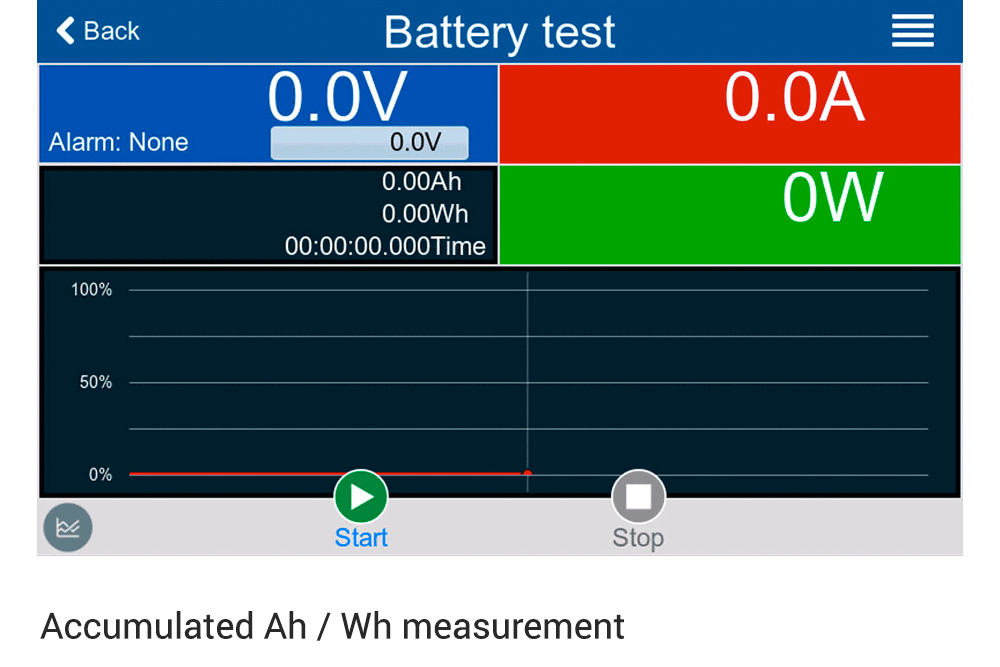

EA Elektro-Automatik’s ELR series comes equipped with an internal Function Generator for accelerated testing and a Discharging Test function for precise energy measurement results. To mitigate high operating costs, many test stations are now adopting regenerative DC electronic loads like our ELR 10000 4U series, which boasts a high regenerative efficiency of over 96%, recycling energy back into the grid and substantially reducing costs.

Case Studies

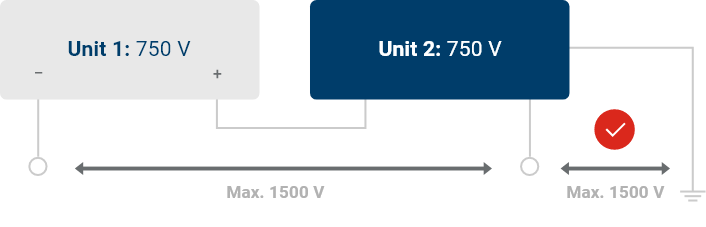

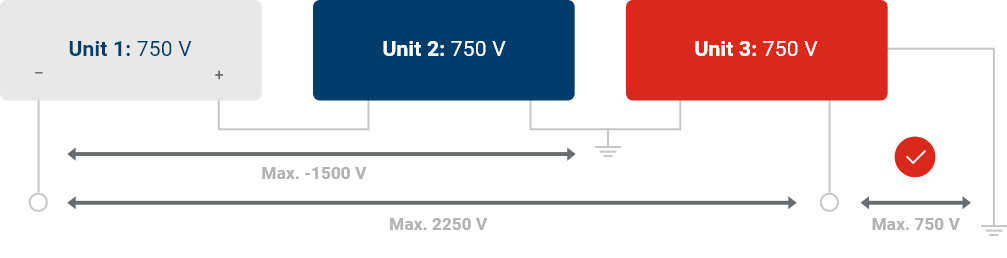

Series Connection and Ultra-low Minimum Load Voltage

Example 1

Example 2

Testing

The EA-ELR 10000 series of regenerative loads is specifically designed for fuel cell testing with an input power of 30kW.

For large-scale testing, these units can be connected in parallel to achieve up to 1.92MW. Our electronic loads come with built-in features like an arbitrary waveform generator and a function generator, offering you unparalleled testing flexibility. Operating at 96% efficiency, our regenerative loads minimize energy loss by feeding it back into the mains, eliminating the need for additional cooling systems and reducing operational costs.

Simulation

Maximize your fuel cell testing simulation capabilities with our EA-PSB 10000 bidirectional programmable DC power supply, engineered for rapid, efficient, and cost-effective evaluations.

This versatile unit enables you to simulate a wide range of fuel cell characteristics, and its scalability allows for testing multiple or high-power fuel cells by connecting units in parallel to reach up to 1.92MW. As a bidirectional solution, the EA-PSB 10000 also serves as an electronic load, offering comprehensive fuel cell testing. Leveraging grid regeneration technology, this power supply operates at an impressive 96% efficiency, channeling absorbed energy back into the local grid.